Ergonomic design assessments

Ergonomics is about fitting the job to the worker — whether it’s physical or psychological aspects of the job. It’s not about making someone adapt to a poor work station set-up or poorly-designed equipment and tools. Nor is it the kind of pseudo-ergonomic “solutions” that do not allow any kind of adjustment or flexibility. (The question always should be: can it be adjusted to meet someone’s needs?)

Just as there’s a long history to ergonomic design hazards, so too is the knowledge about prevention measures to avoid the injuries or disorders. It’s not just a good idea, it’s the law in many countries. (In the US, the only comprehensive regulation is California’s one for hotel housekeepers that takes effect July 1, 2018). Manitoba’s regulation — it does not mention “ergonomics” — is unique for requiring evaluation of “fixes” to ensure they actually work.

Assessing jobs for ergonomic design hazards

Assessments for ergonomic design hazards are required under most Canadian health and safety laws. As an ergonomist, I approach this work as an opportunity to provide training, guidance and resources to individuals and workplaces. The following describes my approach and some of the materials I use and share.

Women usually face different ergonomic design hazards than men, because of the jobs they do. That’s the message delivered by Dr. Karen Messing and other researchers. (There’s a summary about the relevant myths in the New eyes guide.) So it’s important to have a gender lens in doing assessments.

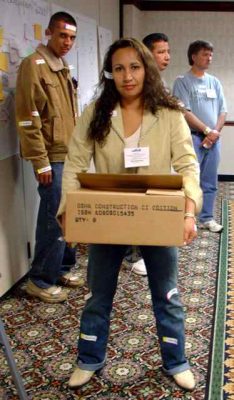

In workshops, participants can assess typical jobs using “ouch” stickers or stickers for each type of ergonomic design hazard. The photos illustrate two examples.

The SOBANE tools developed for the New Eyes guide provide a good starting point. The inspection sheets (ergonomic sections) and SOBANE-style observation tools can be used. With training and experience, committee members and others can learn to use them.

Start with figuring out symptoms and what hazards workers think are responsible for them. The New eyes guide uses a body map and follow-up questions as a starting point. There is a similar tool in the National Institute for Occupational Health and Safety Health Hazard Evaluation of a casket plant (one of the resulting body maps is at the right).

SOBANE specific ergonomic design observation sheets are:

- Computer or monitor work (SOBANE step 2)

- Tools, materials, controls, products (SOBANE Step 2)

- Tools (SOBANE step 2)

- Work station – obstructions (SOBANE step 2)

- Posture – sitting (SOBANE step 2)

- Posture – standing (SOBANE step 2)

- Posture – neck and shoulders (SOBANE step 2)

- Posture – elbows, forearms, hands & wrists (SOBANE step 2)

- Posture – other positions or postures (SOBANE step2)

- Repetition (SOBANE step 2)

- Force – manual material handling equipment (SOBANE step 2)

- Force -vibrating tools (SOBANE step 2)

- Force – wrist and hand strain (SOBANE step 2)

- Force – pushing pulling with arms (SOBANE step 2)

- Force – characteristics of the load (SOBANE step 2)

- Force – lifting – starting position (SOBANE step 2)

- Force – lifting – moving the object (SOBANE step 2)

- Force – lifting – frequency and weight (SOBANE step 2)

- Work environment – general

- Work environment – lighting (SOBANE step 2)

- Work organization or stressors – time issues (SOBANE step 2)

- Work organization or stressors – other hazards (SOBANE step 2)

- Summary of observations (SOBANE step 2)

I also developed a Ergonomic buddy assessment process handout for those wanting to look at computer work stations with co-workers.

Finding solutions

Aside from workers’ suggestions, resources for ergonomic design solutions include:

- Washington State’s ergonomics ideas bank, case studies about prevention activities, and guidelines for multiple sectors;

- the handout, Ergonomic hazards — some myths and realities. Computer work stations: conventional versus current wisdom, developed for the New Eyes guide.

- a formatted version of the Cornell University material about computer mouse issues

- materials about the hazards of standing (the Canadian Women’s Health Network’s Preventing standing hazards, There is no principled reason for denying an employee a seat, and What can be done to improve cashiers)